Discover the Power of Accuracy: Unmatched Performance with Dirt Screens for Sale

Discover the Power of Accuracy: Unmatched Performance with Dirt Screens for Sale

Blog Article

Improve Waste Monitoring With Reliable Dirt Screens for Efficient Recycling

Reputable dust displays play a vital function in this endeavor, offering an effective option to boost waste monitoring systems. By efficiently separating dirt and other impurities from recyclable products, these displays enhance reusing effectiveness and decrease the threat of contamination. In this discussion, we will discover the benefits of trusted dirt displays, the key attributes to take into consideration when choosing them, and successful case studies of their implementation.

Benefits of Trusted Dust Displays

Dependable dust displays offer various advantages for effective recycling processes. These displays play an essential function in waste administration by successfully separating dust, debris, and other impurities from recyclable materials.

Additionally, reputable dirt displays assist to enhance recycling operations by decreasing downtime and upkeep costs. By stopping dirt and debris from getting in the reusing equipment, these displays decrease the danger of tools break downs and linked fixings. This leads to enhanced productivity and cost savings for reusing facilities.

Furthermore, dirt displays add to environmental sustainability. By getting rid of impurities, they help to ensure that the reusing procedure is more effective and efficient, decreasing the demand for added resources and energy. This decreases the total eco-friendly impact of the reusing industry and promotes an extra lasting approach to waste administration.

Just How Dust Screens Improve Reusing Effectiveness

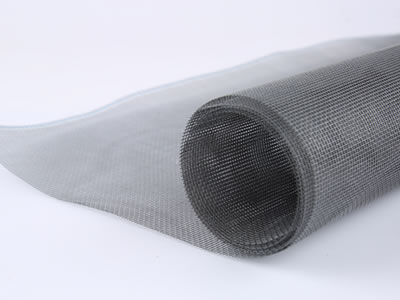

One of the key aspects contributing to the enhanced efficiency of recycling processes is the integration of dirt screens. Dust displays, likewise called trommel displays, are mechanical screening tools that different products by size. These screens play an important duty in boosting recycling performance by getting rid of unwanted dust, debris, and contaminants from the recycling stream.

By including dirt screens right into recycling operations, the top quality of the recycled materials is considerably improved. The screens effectively separate bigger products such as rocks, branches, and plastic bags from the recyclable materials. This guarantees that usable and only tidy products are further processed, lowering the threat of contamination and boosting the worth of completion item.

Dust screens additionally help increase the general ability and throughput of recycling centers. By eliminating undesirable materials early in the procedure, the screens prevent blocking and damages to downstream devices. This enables a smoother and even more constant recycling procedure, leading to greater productivity and minimized downtime.

Furthermore, dust screens add to the sustainability of recycling procedures. By eliminating impurities, the screens lessen the need for extra cleansing actions, saving both time and sources. The boosted effectiveness supplied by dust screens likewise aids reduce energy intake and greenhouse gas emissions related to reusing procedures.

Key Functions to Try To Find in Dust Screens

When choosing dirt displays for reusing procedures, it is very important to think about vital features that optimize performance and effectiveness. These attributes can considerably affect the overall efficiency of the reusing process and make sure a greater return of usable and clean materials.

Another vital function is the durability and toughness of the dirt screens. If they are not developed to hold up against such conditions, recycling procedures frequently include sturdy and abrasive materials that can rapidly put on out displays. Search for displays made from high-grade materials, such as stainless steel, that are immune to abrasion, deterioration, and impact.

Effective dust displays must additionally have a high testing capability to manage big quantities of products swiftly. click here now This makes sure a constant flow of materials through the recycling process, minimizing downtime and increasing performance. In addition, displays with self-cleaning systems, such as vibrating or turning screens, help protect against obstructing and preserve constant performance.

Lastly, take into consideration the convenience of upkeep and availability of the dirt displays. Displays that are simple to clean, change, and keep will save effort and time in the lengthy run, maximizing and lowering functional costs performance.

Incorporating Dirt Screens Into Waste Monitoring Solution

To efficiently integrate dust screens into waste administration systems, it is important to consider the smooth combination of these displays with existing procedures and infrastructure. By incorporating dirt displays into waste monitoring systems, the efficiency and performance of recycling can be significantly enhanced.

One important facet to consider is the positioning of dirt displays within the system (dirt screens for sale). It is vital to purposefully position the displays at key factors in the waste monitoring process to make certain that they catch and get rid of dust and debris successfully. This can be done by installing the screens at the first stages of waste sorting or before product gets in the recycling center

In addition, the compatibility of dirt screens with existing framework should be considered. The displays need to be developed to fit effortlessly right into the existing waste management system without triggering bottlenecks or disruptions. This may need retrofitting or changing the infrastructure to accommodate the screens, making certain a smooth circulation of waste throughout the process.

Furthermore, integrating dirt screens into waste administration systems requires taking into consideration the upkeep needs of these screens. Regular cleaning and maintenance should be factored into the overall waste management plan to ensure that the screens remain to function optimally. This may involve implementing a schedule for cleaning or incorporating automated cleaning devices right into the system.

Study: Effective Application of Dust Screens

A number of successful study have shown the reliable application of dirt screens in waste management systems. These study supply real-world examples of how dirt displays have actually enhanced the efficiency and effectiveness of reusing processes.

One study happened in a reusing facility in a major city. Prior to the application of dirt displays, the center faced obstacles in arranging and separating recyclable products from dust and debris. This caused boosted processing time and reduced the top quality of the recycled materials. After mounting dirt screens, the center achieved substantial improvements. The displays efficiently removed dust and particles, permitting cleaner and more reliable sorting procedures. Therefore, handling time was reduced by 30%, and the top quality of the recycled materials enhanced by 20%.

An additional study entailed a waste management business that implemented dirt displays in their composting procedures. The screens were used to eliminate impurities such as plastic and glass from compost heap. This enhanced the top quality of the compost and enhanced its market price. The firm reported a 40% decrease in the amount of contaminants in the compost, leading to a greater need and increased profits.

Conclusion

To conclude, incorporating reliable dirt displays into waste administration systems can greatly enhance reusing efficiency. These displays effectively eliminate dust and debris from recyclable materials, making certain higher high quality and pureness. Key functions to take into consideration when selecting dust displays include sturdiness, convenience of maintenance, and adjustable setups. Numerous study have actually revealed successful implementation of dirt displays, highlighting their favorable influence on waste management processes. By using these displays, we can boost waste management methods and contribute to an extra lasting future.

Dust displays, likewise understood as trommel screens, are mechanical screening gadgets that separate materials by size.One key attribute to look for in site link dust displays is the dimension of the display apertures. Furthermore, screens with self-cleaning systems, such as vibrating or rotating displays, aid protect against obstructing and keep constant performance.

Additionally, integrating dirt displays right into waste administration systems requires considering the upkeep needs of these displays. Before the implementation of dust displays, the facility faced obstacles in arranging and separating recyclable materials from dust and particles.

Report this page